Vibration testing evaluates how products respond to mechanical vibrations, ensuring they can handle real-world stresses. Vibration occurs in all objects due to external forces, making this testing essential for understanding and mitigating potential issues. This process is crucial for verifying product reliability and durability across industries like aerospace, automotive, and electronics. This article will dive into the essentials of vibration testing, its importance, and the key methods used to perform these critical assessments.

Key Takeaways

- Vibration testing evaluates the mechanical response of products to motion, ensuring durability and reliability across various industries.

- Different vibration testing methods, including sine, random, and shock testing, provide insights into product performance under various real-world conditions.

- Accurate vibration analysis is essential for identifying potential defects and improving product resilience, with factors like environmental conditions playing a significant role in test outcomes.

Understanding Vibration Testing

Vibration testing is a method used to evaluate how structures, systems, or components respond to oscillating forces or motions. It simulates the conditions that buildings or machinery might experience during normal operation, environmental exposure, or extreme events like earthquakes, heavy machinery operations, or transportation.

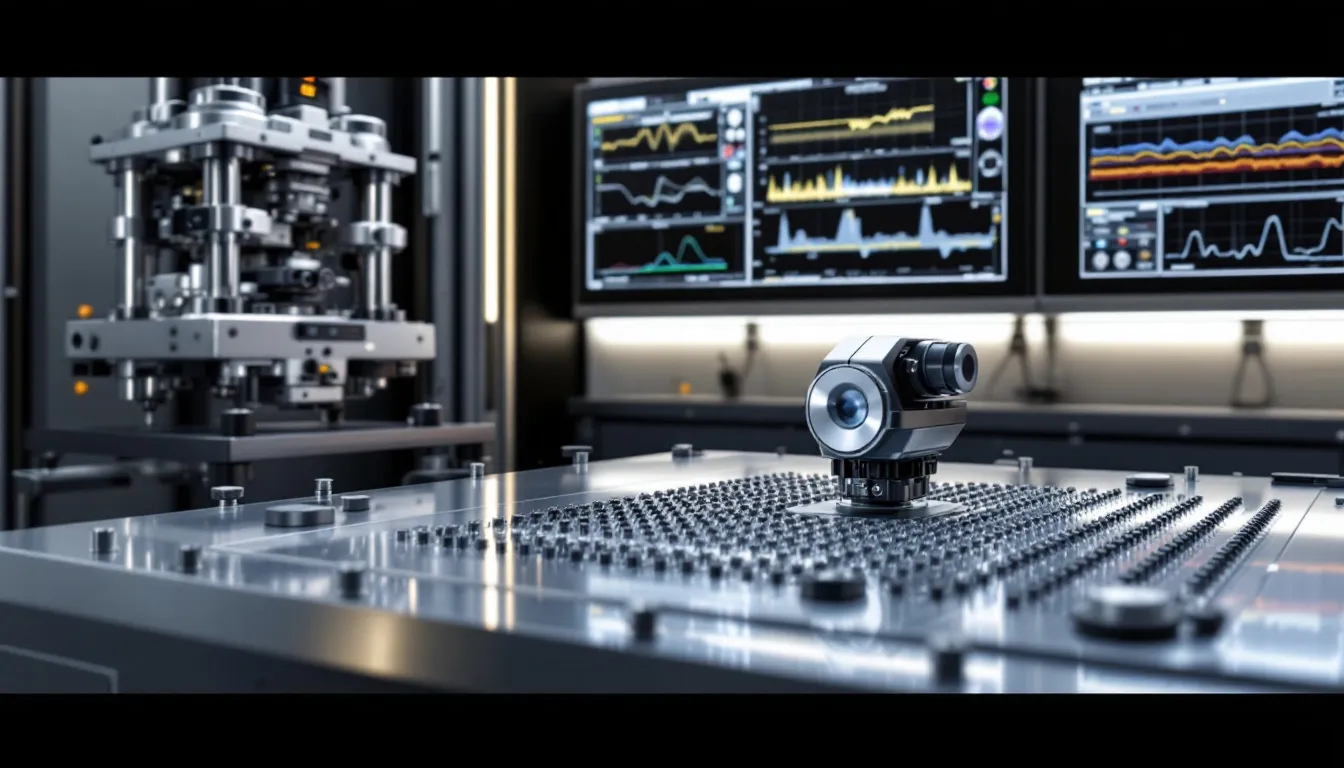

Vibration testing involves applying controlled vibrations, such as shakers, actuators, or vibration tables, to measure how the structure or equipment behaves under various frequencies and intensities. Electrodynamic systems, commonly referred to as EDS, are the primary tools used in vibration testing, offering precise control over the applied forces.

Why Vibration Testing Is Essential?

- Identifies Weak Points

Vibration testing uncovers areas prone to fatigue, wear, or failure, allowing engineers to reinforce or redesign critical elements before real-world deployment. - Prevents Structural Failures

For buildings and heavy machinery, unaddressed vibration issues can lead to structural damage, malfunction, or even catastrophic failure over time. - Enhances Safety

Regular testing ensures that both buildings and machinery can operate safely under expected dynamic conditions, protecting occupants, operators, and nearby environments. - Ensures Compliance with Standards

Many industries and regions have strict regulations (e.g., seismic codes for buildings or ISO standards for machines). Vibration testing helps verify compliance. - Supports Predictive Maintenance

In machinery, vibration analysis helps detect early signs of imbalance, misalignment, or bearing wear, enabling proactive maintenance and reducing downtime. - Automotive Applications

Automotive products undergo vibration testing to ensure structural soundness and vehicle perception, contributing to both safety and user experience.

How It Helps Buildings and Machinery

In Buildings

- Earthquake Resistance: Simulates seismic activity to test structural integrity.

- Occupant Comfort: Identifies vibrations that could cause discomfort or noise in residential or commercial spaces.

- Design Validation: Confirms that building materials and structural designs can handle dynamic loads like wind, traffic, or nearby machinery.

In Machinery

- Performance Assurance: Verifies that machines can operate efficiently without excessive vibration that could affect performance.

- Longevity: Helps ensure components like motors, gears, or bearings are durable under normal and extreme operating conditions.

- Fault Detection: Enables early diagnosis of mechanical problems through vibration signature analysis.

How Vibration Testing Helps Ensure Durability, Safety, and Performance in Buildings and Machinery Across Industries

Vibration testing is a vital engineering tool used across industries to simulate real-world dynamic conditions. It helps assess how buildings and machinery respond to vibration stresses—whether from environmental forces, operational loads, or accidental impacts—ultimately ensuring their durability, safety, and performance.

1. Ensuring Durability

Repeated vibration can cause material fatigue over time. Testing identifies structural or mechanical components that may crack, loosen, or degrade under cyclic loads. In buildings, vibration testing ensures structures can withstand daily dynamic forces like wind, traffic, or machinery. In machinery, it validates endurance under continuous operation. Engineers can refine designs by understanding how different materials and configurations respond to vibration over time. Additionally, vibration testing assists in understanding the dynamic behaviour of satellites during launches, ensuring their structural integrity under extreme conditions.

2. Enhancing Safety

In construction and civil engineering, vibration testing (such as seismic simulation) confirms that buildings can withstand earthquakes or other dynamic events. For rotating equipment like turbines, compressors, or motors, vibration analysis detects early signs of imbalance, misalignment, or bearing failure, preventing accidents or breakdowns. Reduces the risk of injury by ensuring that both structures and machines maintain integrity under stress.

3. Improving Performance

Excessive or uncontrolled vibration can reduce performance or cause energy loss. Testing helps ensure the smooth and efficient operation of machines. In buildings, vibration testing helps reduce structure-borne noise and enhances occupant comfort, particularly in high-rises, hospitals, or schools. In precision industries like aerospace or electronics manufacturing, vibration can impact alignment and accuracy. Testing ensures equipment and structures maintain required tolerances.

Key Industries Benefiting from Vibration Testing

| Industry | Applications |

|---|---|

| Construction & Civil Engineering | Earthquake simulation, vibration isolation, structural health monitoring |

| Manufacturing & Heavy Machinery | Component fatigue testing, predictive maintenance, and design validation |

| Aerospace & Defense | Aircraft fuselage and component testing under flight conditions |

| Automotive | Road vibration simulation for engines, suspensions, and dashboards |

| Energy | Testing turbines, pumps, and generators under operational vibration loads |

| Electronics | Ensuring the durability of PCBs and sensitive components during shipping and operation |

Types of Vibration Tests

Vibration tests come in various forms, each designed to address specific testing needs. Sine testing, random vibration testing, and shock testing are the primary types, each offering unique insights into how a product will perform under different conditions. Shaker systems are commonly used to subject objects to these tests, including swept-sine, random, and transient shocks, to simulate real-world scenarios.

Understanding these tests’ intricacies is essential for ensuring products meet the highest standards of durability and reliability.

Conducting Vibration Analysis

Conducting vibration analysis is a critical step in identifying potential manufacturing defects early and preventing costly equipment failures. This process involves measuring key parameters such as acceleration, velocity, and displacement, with acceleration providing the broadest frequency range for fault diagnosis. By analysing these parameters, engineers can determine a product’s response characteristics and identify any weaknesses or potential failure points.

Accurate data collection is essential for reliable vibration analysis, and factors like base strains and acoustic noise can affect measurement accuracy. Base strains, for instance, can introduce erroneous data by being misinterpreted as acceleration by the sensors. Similarly, acoustic noise can excite accelerometers and the structures under test, potentially obscuring true vibration signals.

Environmental factors, such as temperature variations, also play a significant role in vibration analysis. These variations can influence the material properties of the substances undergoing testing, requiring compensation for accurate results. Advanced testing techniques and careful management of these factors ensure that the vibration analysis provides valuable insights into product performance and durability.

Simulating Real-World Conditions

The main goal of vibration testing is to simulate the actual conditions that a product might encounter. This is done to assess its performance throughout its lifespan. These simulations condense the testing process into significantly shorter durations compared to real-world product testing, providing quick and accurate insights into how a product will perform in various scenarios. Vibration testing can condense years of product life simulation into shorter durations, providing invaluable reliability insights that help manufacturers ensure product durability and performance.

Simulating real-world conditions allows manufacturers to identify potential issues before products reach the market. This proactive approach ensures that products are both reliable and durable, ultimately leading to higher customer satisfaction and reduced warranty claims.

Simulating Real-World Conditions

Vibration testing is a critical process used to simulate the dynamic forces that buildings and machinery encounter during their lifecycle. By recreating real-world conditions, such as traffic, wind, earthquakes, engine operation, or industrial movement, engineers can assess how well a structure or machine can withstand vibration-related stress.

Purpose of Vibration Testing

- Simulate Operational and Environmental Conditions:

Vibration testing mimics the effects of everyday usage, environmental forces, and transportation impacts to ensure durability and performance. - Detect Design Weaknesses:

Testing reveals flaws in materials, connections, and assemblies before they lead to costly failures or safety risks. - Validate Compliance with Standards:

Vibration testing ensures that products meet industry regulations and codes such as seismic design standards for buildings or ISO/ASTM testing protocols for machinery. - Critical Applications:

Random vibration testing is particularly critical for high-risk products such as military equipment and aeroplane components, where failure could have severe consequences.

Simulating Real-World Conditions

In Buildings:

- Seismic Simulation: Shake tables reproduce earthquake forces to test a building’s structural response.

- Traffic and Wind Vibration: Buildings near highways, railways, or tall structures are tested for sustained, low-frequency vibrations from nearby motion or wind loads.

- Occupant Comfort & Noise Control: Vibration tests help design quieter and more stable floors, walls, and ceilings.

In Machinery:

- Operational Load Testing: Machines like engines, pumps, and turbines are tested under working conditions to simulate real dynamic loads and RPM ranges.

- Transport Vibration Testing: Equipment is exposed to vibration profiles mimicking transport by truck, rail, or air to ensure it survives shipping and handling.

- Rotational and Impact Vibration: Simulates continuous or sudden forces to validate moving parts and structural housing durability.

Benefits of Simulated Vibration Testing

- Improved Durability – Identifies weak points that might fail under real-life vibration stresses.

- Enhanced Safety – Prevents catastrophic failures in buildings or mechanical systems.

- Optimised Performance – Ensures equipment runs smoothly with minimal vibration, noise, or energy loss.

- Predictive Maintenance – Informs condition monitoring systems to catch early signs of wear or imbalance.

Advanced Vibration Testing Techniques

As technology and engineering demands evolve, advanced vibration testing techniques are increasingly used to simulate complex real-world conditions with higher precision. These techniques go beyond basic shake tests to provide deeper insights into structural behaviour, machine health, and long-term durability. Composite vibration testing methods, such as sine-on-random and random-on-random testing, are examples of advanced approaches that combine multiple vibration profiles for more comprehensive analysis.

1. Multi-Axis Vibration Testing

Applies vibration in multiple directions (X, Y, and Z axes) simultaneously to replicate complex motion patterns. The analysis of axial testing involves breaking down vibration into these three axes, providing a detailed understanding of how forces interact in different directions.

- Use Case in Buildings: Simulates seismic activity or wind-induced motion on multiple axes.

- Use Case in Machinery: Tests rotating or moving equipment under combined axial, lateral, and vertical loads for more realistic stress evaluation.

2. Random Vibration Testing

Applies unpredictable, broadband frequency vibrations to simulate real-world environments (like road or air transport).

- Use Case in Buildings: Models vibrations from traffic, trains, or industrial activity near structures.

- Use Case in Machinery: Mimics chaotic forces experienced during machinery operation or shipment.

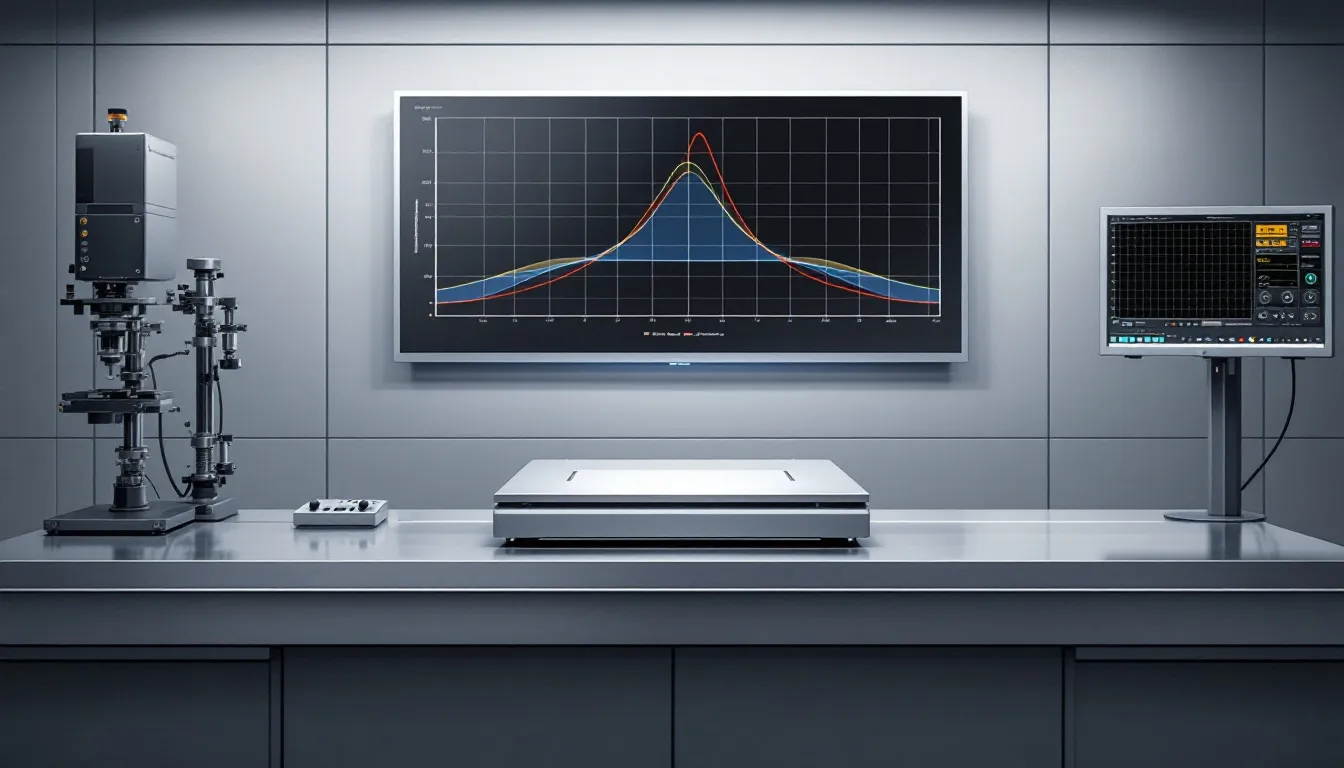

3. Sine Sweep and Resonance Testing

Gradually increases frequency to identify resonance points—frequencies at which systems naturally oscillate with maximum amplitude.

- Use Case in Buildings: Identifies structural resonance that could amplify seismic or wind response.

- Use Case in Machinery: Detects resonance in rotating components that could cause fatigue or failure.

4. Seismic Simulation (Shake Table Testing)

Uses large hydraulic or electrodynamic shake tables to replicate earthquake ground motion in real time.

- Use Case in Buildings: Tests full-scale building models or structural elements under simulated earthquake conditions.

- Use Case in Machinery: Validates the seismic resistance of critical equipment like generators or control systems in earthquake-prone areas.

5. Operational Modal Analysis (OMA)

Determines the dynamic properties (natural frequencies, damping ratios, mode shapes) of structures while they are in normal use—no artificial excitation required.

- Use Case in Buildings: Monitors real-time vibration responses from environmental loads to assess long-term behaviour.

- Use Case in Machinery: Identifies structural issues during actual operation without interrupting workflows.

6. Condition Monitoring & Vibration Signature Analysis

Continuously records and analyses vibration patterns using sensors (accelerometers, velocity probes) to detect anomalies.

- Use Case in Buildings: Tracks structural health over time to detect degradation or damage.

- Use Case in Machinery: Enables predictive maintenance by identifying early signs of misalignment, imbalance, or wear.

7. Finite Element Analysis (FEA) for Vibration Modelling

A simulation-based technique that models vibration behaviour virtually before physical testing.

- Use Case in Buildings: Predicts structural response to different vibration loads during the design phase.

- Use Case in Machinery: Models the dynamic response of machine parts under various operating conditions, saving prototyping costs.

8. Environmental Stress Screening (ESS)

Combines vibration with temperature, humidity, or other stresses to uncover hidden defects.

- Use Case in Buildings: Stress-test systems like HVAC, electrical conduits, or mounted equipment.

- Use Case in Machinery: Tests electronics and mechanical systems under combined environmental loads for reliability.

Summary

Vibration testing is crucial for ensuring durability, safety, and performance, a cornerstone of quality assurance and risk mitigation in both buildings and machinery. Simulating real-world dynamic conditions helps engineers identify weaknesses, enhance designs, comply with regulations, and prevent costly failures or accidents. It ensures that systems across various industries are built to last, are safe to operate, and perform reliably under stress. Whether it’s a skyscraper or an industrial motor, vibration testing plays a key role in creating safer, more reliable systems.

Advanced vibration testing techniques are essential tools for modern engineering, allowing a deeper understanding of how buildings and machinery respond to real-world stressors. From multi-axis simulation to real-time monitoring and virtual modelling, these methods help ensure structures and equipment are not only compliant and safe—but also efficient, resilient, and ready for long-term performance.

Frequently Asked Questions

Can I measure vibrations with my phone?

Yes, many smartphones have built-in accelerometers that can measure vibrations. There are also apps available that use these sensors to record vibration levels. However, smartphone measurements may not be as accurate or sensitive as professional vibration testing equipment, so they are best suited for basic or preliminary assessments.

How do you check vibration levels?

Vibration levels are typically checked using specialised sensors such as accelerometers, velocity sensors, or displacement sensors attached to the object being tested. The sensors capture vibration data, which is then analysed using vibration analysers or data acquisition systems to determine parameters like amplitude, frequency, and acceleration. These sensors can be attached directly to the test object or the surface it rests on, ensuring accurate data collection for analysis.

How to diagnose vibration?

Diagnosing vibration involves analysing vibration patterns and parameters to identify the source and nature of the vibration. This can include checking for imbalances, misalignments, looseness, bearing faults, or resonance. Techniques such as frequency domain analysis (FFT), time domain analysis, and vibration signature analysis are commonly used to diagnose vibration issues.

What are acceptable vibration levels?

Acceptable vibration levels depend on the type of equipment or structure and the applicable standards or guidelines. Different industries and applications have established thresholds for vibration amplitude, frequency, and acceleration to ensure safety and performance. It is important to consult relevant standards (e.g., ISO, ANSI) or manufacturer specifications for specific acceptable vibration limits.

Add comment